Address: Steel Industry Zone, Laobian District, Yingkou City, Liaoning Province

Tel: 0417-3907766

Mobile: 18341738585

Mobile: 13314010101

Email: ykwynlcl@163.com

I. Product introduction

With the rapid development of social economy, facing more and more in the field of ultra-fine powder processing superfine powder application requirements, the traditional ultra-fine powder processing equipment for common characteristics and low capacity of the can has been difficult to meet the market demand for real estate, severely restricted the development of modern super fine powder processing enterprises, based on the current market demand, combined with dongsheng yu Chen mill production experience for many years, the introduction of Taiwan and Germany ultrafine grinding technology, design develop a set of crushing, conveying, ultrafine grinding, classification, and set in a new type of superfine grinding equipment, vertical milling machine.

Super fine vertical pulverizer can be widely used in chemical industry, metallurgy, non-metallic ore and other industries, especially in the field of white non-metallic ore super fine pulverizer, with excellent performance, it can provide high quality fillers and additives for papermaking, coating, plastic, rubber, PVC, ink and other industries. Can be widely used in calcium carbonate, talc, iron powder, carbon black, bentonite, molybdenum powder, calcite, marble, limestone, dolomite, barite, talc, kaolin, dolomite, wollastic, gypsum, feldspar, pyroxene and other non-metallic minerals large-scale ultra-fine powder processing.

II. Working principle

Vertical mill, there are many different forms, but its working principle are basically the same, all of these forms of mechanical with roller (or the equivalent of the grinding powder parts), roller, moving along the horizontal circular trajectory on the mill by external pressure on roller of vertical, make the magic mill wheel material is extruded and shear joint action, and to be able to crush. The grinding process of materials is as follows: the electric motor drives the rice disc to move and is crushed by the grinding roller. The crushed materials leave the grinding disc and are taken by the high-speed upward airflow to the integrated classifier of vertical grinding. The coarse powder returns to the grinding disc after passing through the classifier, and is then pulverized again. In the vertical mill, the material is transported by air, which requires a large airflow air velocity. Therefore, waste gas can be used and the drying and grinding operation can be carried out at the same time. In production, the use of vertical grinding of its grinding parts in a variety of forms, such as cylinder, cone body, spherical, etc.

Grinding roller surface also has plane, arc, convex surface. The force exerted on the grinding roller to use the grinding powder track of the grinding roller to contact with the material bed is spring pressure, hydraulic pressure and so on.

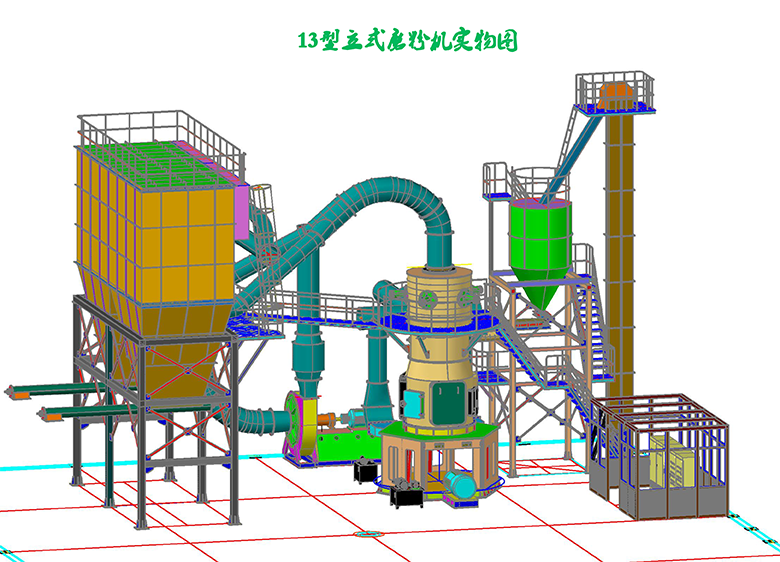

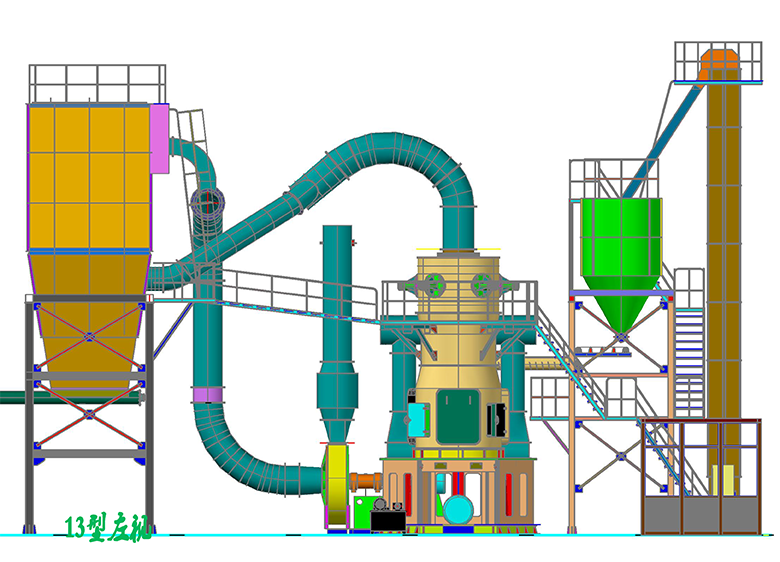

III. Product structure

Vertical grinding machine is mainly composed of powder separator, grinding roller device, grinding disc device, pressure device, reducer, motor, shell and other parts. The separator is a vertical pulverizer.

The utility model relates to an efficient and energy saving powder selecting device. The grinding roller is used to crush and crush the material. The grinder is fixed on the output shaft of the reducer, which is the place where the grinding roller presses the material. The pressurizing device is the component that provides grinding pressure for the grinding roller, which provides sufficient pressure for grinding materials.

IV. Product advantages

1. Original research and development technology, leading the industry.

2. High production capacity, high fineness, and low energy consumption (20%-40% less energy consumption of ball mill than that of ton products)

3. 5 sets of grading wheels are designed with dynamic balance correction, high cutting precision, moderate fine powder content, uniform particle size distribution and good adaptability.

4. the whole system is a negative pressure system, dust pollution, vibration, noise, environmental protection and energy saving, in line with the national environmental requirements.

5. Vertical mill main machine, fan, classifier and other equipment are all imported frequency conversion control system, stable automation.

6. The grinding and wear-resisting parts in the main machine are all made of wear-resisting material to increase the service life.

7. Super fine powder produced by the host machine has narrow particle size distribution, controllable 2um content, good activation effect and low oil absorption value.

8. Automatic computer control can be used in the grinding process to add grinding AIDS to improve the added value of products.

9. Widely used in the large-scale production and processing of nonmetallic powder.

For example: papermaking, non-woven cloth, artificial marble, paint coating, wire and cable, PVC pipe, PVC edge strip, filler master, rubber and so on.

● Strong drying ability

Because the hot air in the mill directly contact with the material, drying ability is strong, energy saving, through adjusting the hot air temperature, can meet the requirements of different humidity materials.

● Easy to operate

(1) Equipped with automatic control system, remote control can be realized, easy to operate.

(2) It is equipped with a device to prevent direct contact between the roller sleeve and the millstone lining plate, so as to avoid destructive impact and violent vibration.

● Stable product quality

Because the material stays in the mill for a short time, it is easy to detect and control the particle size and chemical composition of the product, reduce repeated grinding, and stabilize the product quality.

● Easy maintenance

It is convenient and quick to replace roller sleeve and lining plate by inspecting oil cylinder and turning arm, thus reducing the loss of stop.

● Environmental protection

Small vibration, low noise, and the whole equipment is sealed, the system works under negative pressure, no dust spill, the environment is clean, meet the national environmental requirements.

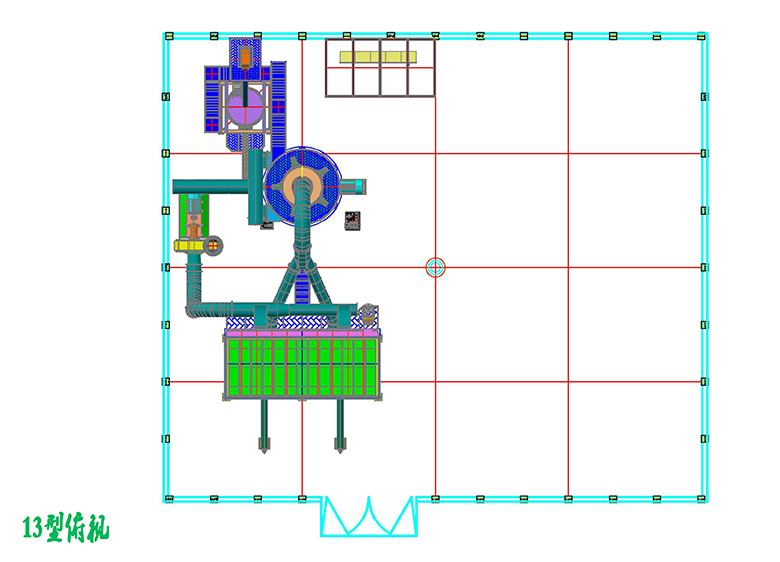

V. Process flow

According to the position of humidifying tower and dust collector, there are two different layout schemes, namely three fan system and two fan system. Whirlwind dust collector is used for product collection. This arrangement can reduce the working negative pressure of the system and the amount of gas passing through the dust collector. Electric dust collector can also be used as dust removal equipment; The dust collecting device can be electric dust collecting device or bag dust collecting device. The grinding gas directly enters the dust collecting device. The system reduces the number of equipment and simplifies the system configuration.

PREV:NO MORE

NEXT:Raymond mill